Table of Contents

- What is Roof Flashing?

- Roof Flashing

- Sizes for Roof Flashing

- Roof Flashing Materials

- Types of Roof Flashing Sealant

- Roof Flashing Techniques

- How to Install Roof Flashing

- Step Flashing with a Wall Corner: How to Install

- How to Install Step Flashing where there is no Wall Corner

- How to Install Counter Flashing on a Chimney

- How to Install a Roof Plumbing Flashing Boot

- Is It Possible to Reuse Old Roof Flashing?

- When You Should Fix a Roof Flashing Leak

- How to Repair Roof Flashing

What is Roof Flashing?

Roof flashing is a thin, galvanized steel material that roofers use to divert water away from roof areas where the roof plane meets vertical surfaces like walls or dormers. Flashing is used to protect roof features such as skylights, chimneys, vents, and chimneys. The flashing should allow water to flow down the sides and direct it towards the shingles, not the roof deck.

Water could drip from the crevices between the walls and roof if there was no flashing.

Roof leaks are most often caused by damaged or poorly installed flashing. According to the Federal Emergency Management Agency (FEMA), improper roof flashing can lead to wood rot or even deck collapse. If you’ve ever looked at your roof flashing and wondered what it was, there are likely many questions.

What is roof flashing?

Why is roof flashing important?

How do I install roof flashing?

How do I go about repairing roof flashing?

Let’s get started.

Roof Flashing

There are nearly as many roof flashing types as there are roof parts. Each roof feature requires protection. These are the main types of roof flashing that you should be familiar with:

- Continuous Flashing Because it functions a lot like an apron, continuous flashing is also known as “apron flashing”. It is a single, long piece of metal that carries water to the shingles below. It will be difficult for long pieces of continuous flashing to flex as the home expands or contracts with the seasons. It could crack, warp or fail to keep out water if left alone. Because of this behavior, long pieces are designed to move with your home by having expansion joints.

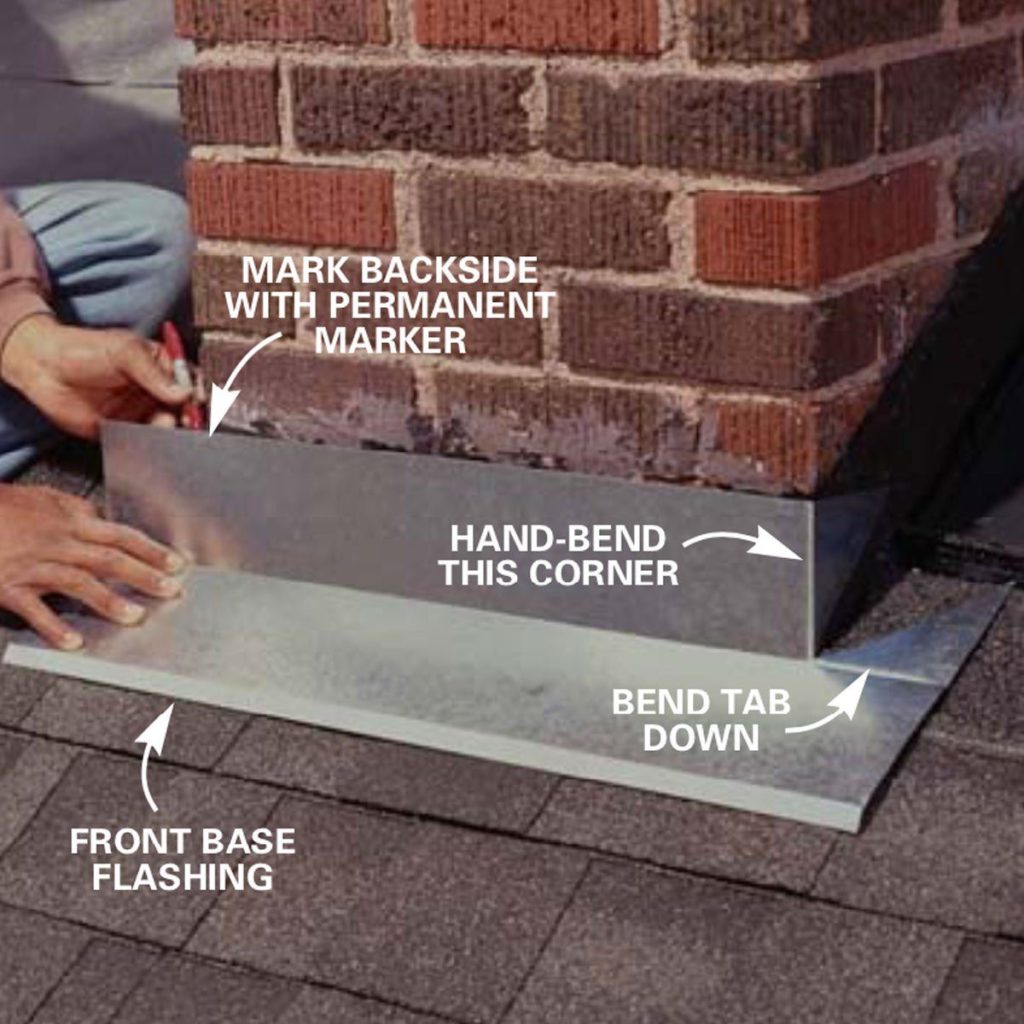

- Base Flashing: There are some roof features that require two pieces, like chimneys. This ensures that rain falls only to a flashing surface, which directs it downwards. It is also difficult to install flashing around chimneys. Two-part flashing has another advantage: The roof materials can expand and contract naturally, so the entire system remains secure. The bottom flashing, also known as apron flashing, is the bottom-most piece.

- Counter-Flashing: Placed across from or above the base flashing. Counter-flashing completes the system.

- Step-Flashing: Step flashing is a rectangular piece of flashing that has been bent 90 degrees in its center. It’s used for flashing from roof to wall. To ensure water flow away from the wall, multiple pieces of flashing are installed in layers with shingles. Find out how to install it in the below paragraphs.

- Skylight flashing: Although some skylight manufacturers include flashing, roofing professionals may have to make it or buy it separately.

- Valley flashing: Open valleys use metal flashing to protect the roof’s critical areas.

- Drip edges: The roof’s edge has thin metal flashing. This allows water to drip off the roof and not damage the home.

- Kickout flashing: Professional roofing contractors need to be able to connect the gap where step flashing ends with the gutter. Kickout flashing directs water away from the wall into the gutter. Below, learn how to install kickout flashing.

There are many pre-made flashing pieces that you can buy, but roofing professionals can cut their own flashing from sheet metal. They will use tinning scissors to cut the sheets and bend them to their exact dimensions while they are on the roof. Be careful if you go to a shop to purchase your flashing; there are other types of flashing are not designed to be installed on roofs. Head flashing, for example, protects windows and doors from water damage.

Sizes for Roof Flashing

You need to be careful about the size of your roof flashing if you want to repair or install it. Your plumbing vent flashing should be large enough that it can surround the vent. It should not be wider than the vent’s diameter.

Your step flashing pieces must be at least 10 inches long (254 mm), and at most 2 inches (50mm) wider than your exposure to the shingle. 3-tab shingles have an exposure of 5 5/8 inches (143mm). Flashing is usually 10-by-8-inch (253mm x 203mm) in size. These 8 inches will cover most shingles. You can also use the same size to cover longer exposures on Nordic Nordic, shingles.

Roof Flashing Materials

In the past, flashing was made from lead or lead-coated materials by roofing professionals. Dallas roofing professionals prefer to use other materials.

- Aluminium flashing is simple for roofing professionals and lightweight. Aluminum must be coated to avoid reaction with alkaline surfaces. To prevent corrosion, the aluminum flashing should not be used in concrete or masonry areas.

- Copper roof flashing can also be soldered well and is malleable. It is also extremely durable and lasts a long time. However, some homeowners don’t like the patina (a green film) it develops, while others prefer it. Copper flashing will still be found around chimneys.

- Steel is the most popular material for flashing. It is malleable and has aesthetic value. When galvanized, it is also corrosion-resistant.

Your roofing contractor may need to use a particular material for flashing. You may also be required to specify a minimum thickness. Building codes usually require 26-gauge galvanized iron as a minimum. To ensure you are following local codes, it is important to always verify.

If you are in Florida, your building codes may require modified bitumen roofing tape.

- Modified Bitumen Roofing Tape : Modified Bitumen is a tough, water-resistant material. It can be used for roof flashing by being made into tape. Your building code will approve the tape that you use and the minimum width.

Types of Roof Flashing Sealant

You will need to seal your roof flashing with a sealant. Although roofing professionals may use nails for flashing, they will need to decide whether to attach the roof plane or to the vertical wall. The flashing can be damaged by shifting bricks or wood if it is nailed to all of them. The flashing will stay in place if it is attached only to the roof or vertical wall. This allows for the building materials to expand and contract with the seasons.

Roofing concrete: The waterproof seal is created by roofing cement. It is usually applied with a trowel by roofing professionals.

Roof Flashing Techniques

Before you can learn how to install roof flashing, it is important to know that there are three main methods. Each one works for different areas of the roof. There are specific flashing types that correspond with certain techniques.

- Step Flashing: Step flashing is recommended for roof faces that meet walls, such as where a dormer extends from the roof. It is possible for water to flow down the wall, past the shingles, and into the building below. Step flashing makes sure that water does not flow down the wall, but instead ends up in the gutter. It is installed in steps with layers of shingles between so that water flows down each step and into the roof.

- Counter-Flashing: Counter-flashing is used to flash chimneys. There are two types of flashing involved. The base flashing is located around the bottom edge of the chimney. Counter-flashing is embedded in the chimney’s masonry. The counter-flashing is placed over the base flashing so that water doesn’t get behind it. Counter-flashing is used by construction professionals for many other purposes. However, it always requires a second piece flashing that has been set off from the original.

- Plumbing vent boot flashing: Vent flashing consists of a cylindrical piece that fits around the vent. The shingles are placed over the boot or base. Water will run around the vent because of the height of the boot

How to Install Roof Flashing

Disclaimer: Professional roofers should install roof flashing. They are familiar with best practices, safety requirements, and local building codes. These instructions are intended to assist homeowners in understanding what to expect from a professional roofing company.

Step flashing on a roof is the most difficult because it must be done step-by-step just like you are shingling up the roof. Here are some best practices to follow. To cover the flashing, step flashing should be installed first. The flashing must be replaced with siding if this is a repair job. According to the National Roofing Contractors Association, the step flashing must extend 8-14 inches above the shingles.

Before you install your flashing, make sure you check if there is a corner on the roof facing of the wall you are installing.

If it has a corner, please follow the first installation procedure. If the corner is not present and it looks more like the image below then follow the second installation process.

Step Flashing with a Wall Corner: How to Install

You will need to make a corner flashing part if the wall corner is located on the roof. These instructions will show you how to make a corner piece as well as how to install step flashing.

- Step 1: Install the underlayment and your shingles to the point where the wall starts. The corner flashing or the first piece will rest on a single shingle.

- Step 2: To create corner flashing, use your tin-snips to cut a 45-degree line from the outside corner to the center fold. Cut along the center fold, and then remove the triangle. This will allow the step flashing to be bent around the corner. You can purchase pre-bent pieces to make corner flashings, or you can bend a piece of corrugated aluminum.

- Step 3: Turn the corner and flash the light tightly around the corner. Make sure it is flat and at least 8 inches from the shingles. You will need to nail it in place using two nails, one for each side of its top edge.

- Step 4: Get a second piece flashing and place it in its place. Turn it so it covers the corner flashing.

- Step 5: Take out the second piece and apply the sealant to the area where flashing will be visible. Next, place the piece on the ground. Then, hammer one nail into the flashing at the bottom. This will allow the next row to cover it.

- Step Six: Complete a complete shingle course over this piece of flashing.

- Step Seven: You must now apply step flashing to the area where the next set of shingles will begin. The flashing must be at least 3 inches in length. Place the flashing and seal it with sealant.

- Step Eight: Keep switching between flashing and shingles until you reach the top.

- Step Nine: In order to flash the peak of your roof, you’ll need another piece of flashing. Cut a piece of step flashing about halfway into the fold.

- Step Ten: After cutting one side, bend the opposite side to match the peak. This piece can be secured with roofing cement and one nail at the base. Later, you’ll cover it with a ridge shingle.

How to Install Step Flashing where there is no Wall Corner

You don’t need to install a corner flashing piece if your roof face connects with the wall without creating a corner. Kickout flashing is required to guide water into the gutter. Professional roofers may make their kickout flashing in copper by hand, but if you use galvanized steel it will not bend well. You can instead buy a pre-made kickout flashing part.

This is how to install step flashing and kickout.

- Step 1: Install your kickout flashing against the wall at the base of your roof. Take the roofing cement and remove it.

- Step 2: Lay the first piece step flashing on top of the starter strip. Make sure it leads to the kickout flashing. To attach it to the roof deck, use roofing cement and two nails. You will need to place the nails at the base of the step flashing so that you can nail them into the deck. Place the nails high so that the next set of shingles can cover them.

- Step 3: After the kick flashing has been completed, apply a shingle. Apply sealant to the flashing’s base. Apply sealant to the flashing base. The flashing base and nail are covered by the bottom of your shingle.

- Step 4: Complete the whole shingle course.

- Step 5: To finish the step flashing you will need to use the corner piece as described above.

How to Install Counter Flashing on a Chimney

The chimney flashing must be installed while the mason is laying bricks and mortar. Or the roofer will need to create a ridge for counter-flashing. After the flashing is installed, the roofer must seal the inden.

- Step 1: Make sure the chimney’s flashing is in good order. Attach it to the roof according to the manufacturer or mason, and then cover the shingles. You can also install step flashing on the chimney side if you didn’t receive base flashing.

- Step 2: Make a cut in the chimney using a diamond bitsaw/diamond grinding disc. Here is where the counter-flashing will be hung.

- Step 3: Add the counter flashing to the indent. Make sure it is at least 2 inches above the base flashing.

- Step 4: Use roofing cement for the securement of the counter-flashing between the base flashings and the chimney.

- Step 5 : Fill the indentation with roofing caulking so that the counter-flashing hangs securely.

How to Install a Roof Plumbing Flashing Boot

It is usually easier to install a roof plumbing vent than to flash a chimney. This is how it’s done:

- Step 1: Install shingles in the normal way up to the base the plumbing vent.

- Step 2: Install the flashing/boot onto the plumbing vent so that the base rests on the shingles. Apply sealant to secure the flashing.

- Step 3: Push the flashing down to its original position.

- Step 4: Install the next set of shingles. Allow the shingles to cover the flashing at the plumbing vent.

- Step 5: To make space for the vent, cut a circle from the shingles as shown below.

- Step Six: To seal the edge of your shingle, place roofing cement underneath it. Make sure you nail it exactly where you would normally.

You may also need to know how to install other types of roof flashing. Red Ladder Roofing will explain in a future article how to install drip edge flashing and how you can install metal valley flashing.

Is It Possible to Reuse Old Roof Flashing?

It is a good idea to replace all flashing on a typical roof replacement job. The lifespan of a new roof may be cut short by old flashing. There are very limited situations where flashing can be reused by a roofer. If a roofer repairs a relatively new roof, and the flashing looks in good condition, then it might be salvageable.

Your roofer will have to carefully remove your flashing to determine if it can be reused. The flashing will be inspected by your roofer before being reused. Your roofer will need to remove the flashing if he is installing shingles around it.

Step flashing is a more difficult type of flashing to reuse as it can be harder to separate the old shingles from it without causing damage. A roofer will typically replace step flashing on new roofs.

Your roofer should not add flashing to the existing flashing. A roof should have only one layer of flashing.

When You Should Fix a Roof Flashing Leak

It is possible that you are curious about what flashing has been damaged and when it should go to be replaced. You can check your flashing for the following:

- Holes, bending, or other obvious physical damage.

- Corrosion and rusting.

- Missing or loose nails.

- Missing or dried out sealant.

- Flashing that is loose.

You may have to replace flashing if you notice any of these issues.

It’s possible that you will need to replace the flashing during a roof installation. It depends on several factors. It is possible to reuse original flashing if it is in good condition and can be taken out without damaging it. If you want a waterproof roof, it is important to put your money into proper fit and seal.

How to Repair Roof Flashing

Roof flashing is best left to professionals. Your roof is too important to risk damage during a self-install.

- Step 1: Gently lift up any shingles that are covering or surrounding the flashing. This may also involve removing damaged flashing pieces.

- Step 2: Use your chisel to gently remove any asphalt cement that you find.

- Step 3: If the flashing problem was caught before the leak started, the roof structure and parts should not be damaged. It is important to inspect for any damage. You will need to repair any damage before you reinstall the flashing.

- Step 4: Now, install the flashing and shingles again. To ensure flashing is water-resistant, make sure you follow the instructions as described above.

Roof flashing may not be the most striking element of a roof but it is the most crucial. We recommend that you contact Red Ladder Roofing if you notice flashing problems on your roof. Professionals can solve your flashing issues and answer any questions about your particular roof.